Powder Coating has quickly become the high quality go-to finish medium for high-end, heavy-use industries including applications for automotive components; motorcycle and bicycle parts; agricultural equipment; mass transportation; heavy moving equipment; recreational equipment; medical equipment and fixtures; consumer and commercial appliances, agricultural equipment, architectural and signage components, computer and electronic encasements; gym, exercise and sporting equipment; office furniture; outdoor furniture; manufacturing and tooling equipment; residential and commercial construction.

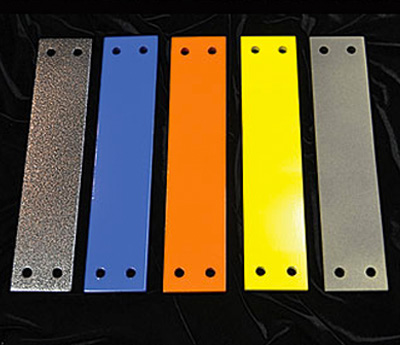

As a new finish or restoration finish, there is an endless array of colors, textures, and finishes in powder that can virtually match any paint in production.

Application of powder involves the proper preparation of the substrate, or part, to be finished. Once the blasting and/or cleaning is complete, the part is covered with a dry powder made from a polymer base. The powder adheres to the surface with an electrostatic spray deposition (ESD) process.

The part is then moved to an oven where the powder cures and melts into the substrate surface with an ultra-strong bond adhering to the part rather than just adhering in a layered process; such as paint. Once cooling is complete, the part is completely cured and ready for a long lifetime of use.

Most powder surfaces are applied to a metal substrate, but advances in the industry have made it possible to apply powder non-metallic substrates, such as composites and plastics.

Not only is the cost of a powder coated finish is typically much less than painted finishes due to the labor time and associated regulatory costs of painting, but the turn-around time for the process is a fraction for that of painting. Thus, you will have less lead time or production down time on your project.

On average, powder coated surfaces by study, are up-to 50 times more durable than industrial painted surfaces. This means that you have less cash spent on re-finishing a product as the powder will outlast paint.

The world looks at Powder Coating with a smile… Not only does it provide a superior finish and uniformity than a painted finish, but the process has a zero footprint impact on the earth. Unlike paint, powder is recyclable, and has no toxic VOC, or emissions.